Introduction

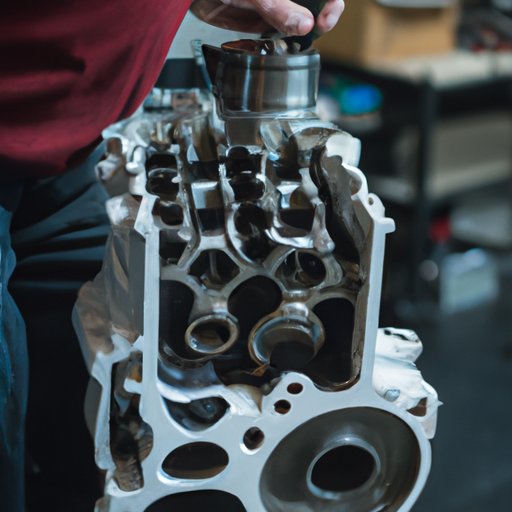

Rebuilding an engine can be a daunting task, especially when it comes to budgeting for the job. The cost of rebuilding an engine is not fixed and can vary significantly depending on a variety of factors. This article explores the factors that impact the cost of rebuilding an engine and offers tips on how to lower the cost.

Exploring the Factors that Impact the Cost of Rebuilding an Engine

When it comes to budgeting for an engine rebuild, there are several factors to consider. These include the type of engine, parts and labor costs, and location.

Type of Engine

The type of engine plays a big role in determining the cost of a rebuild. Smaller engines, such as those found in cars and trucks, tend to be less expensive than larger engines, such as those found in boats and industrial machinery. This is because smaller engines typically require fewer parts and less labor.

Parts & Labor Costs

The cost of parts and labor is one of the biggest factors that determine the cost of an engine rebuild. Parts can range from a few hundred dollars to thousands of dollars, depending on the type of engine and the extent of the rebuild. Labor costs will also vary by location, with some areas charging higher rates than others.

Location

The cost of an engine rebuild can also vary by location. In some areas, the cost of labor may be higher due to a lack of qualified mechanics or the cost of living. Additionally, the cost of parts may be higher in certain areas due to shipping costs or taxes.

How to Lower the Cost of Rebuilding an Engine

If you’re looking to lower the cost of an engine rebuild, there are a few things you can do. Shopping around for parts and labor is one way to save money. You can also consider buying used or rebuilt engines instead of rebuilding your own. Doing some of the work yourself is another way to lower costs.

A Step-by-Step Guide to Rebuilding an Engine on a Budget

If you decide to rebuild your engine yourself, here’s a step-by-step guide to help you do it on a budget. First, gather all the necessary tools and supplies. Then, disassemble the engine and clean all the components. Once everything is clean, reassemble the engine and test it. Finally, inspect the engine to make sure it’s running properly.

Comparing DIY vs Professional Rebuilding Costs for an Engine

When it comes to rebuilding an engine, there are pros and cons to both DIY and professional options. If you choose to do it yourself, you’ll have more control over the process and will likely save money in the long run. However, if you go with a professional, they’ll have access to better tools and resources, and may be able to finish the job faster. Ultimately, the cost comparison between DIY and professional engine rebuilding depends on the type of engine, the extent of the rebuild, and the location.

What You Need to Know About the Price Tag for Rebuilding an Engine

When budgeting for an engine rebuild, there are a few common misconceptions to be aware of. First, you should keep in mind that the cost of parts and labor can vary significantly. Additionally, there are additional costs to consider, such as taxes and shipping. Finally, it’s important to remember that the cost of rebuilding an engine can be affected by the type of engine, the extent of the rebuild, and the location.

Conclusion

The cost of rebuilding an engine can vary significantly depending on a variety of factors. It’s important to keep in mind the type of engine, parts and labor costs, and location when budgeting for an engine rebuild. Additionally, there are ways to lower the cost of rebuilding an engine, such as shopping around for parts and labor, considering a used or rebuilt engine, and doing some of the work yourself. Finally, it’s important to be aware of the common misconceptions about the price tag for rebuilding an engine, as well as any additional costs to consider.